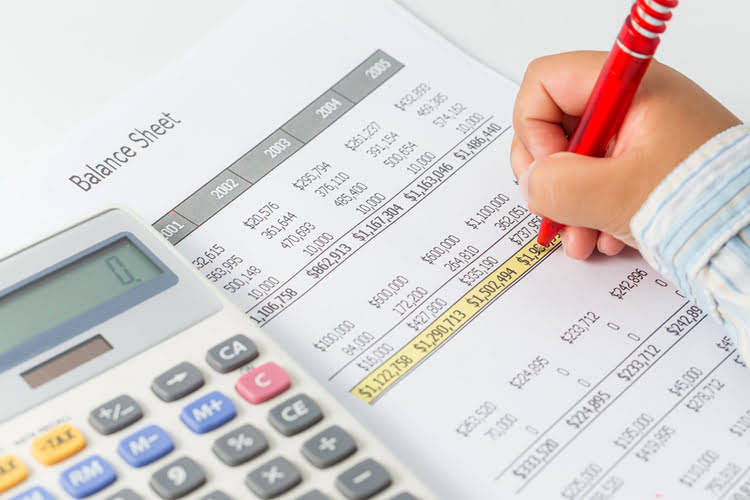

Jami has collaborated with clients large and small in the technology, financial, and post-secondary fields. Job costing offers several compelling benefits that make it indispensable for businesses dealing with customized production. Job costing finds its natural home in industries where each customer order or project has unique specifications and requirements. (i) Material costs of the job are based on material requisitions or materials issue analysis sheet. (viii) The systematic costing records maintained for each job provide a reliable database for statistical trend analysis of costs over a period of time. Job costing is used for comparatively smaller works of shorter duration.

Direct material costs 🔗

We’ll go over all, plus explain when to use job order costing and provide an example of a job cost sheet to make sure the definition is clear. Several features of job costing can help you determine whether it’s the right method for your company to use. Job costing is often compared to process costing, another way of determining costs. Companies that produce multiples of the same product often use process costing. Meanwhile, companies that produce “one-off” or unique products use job costing. By tracking costs on a per-job basis, businesses can gain insights into the features of job costing profitability of each job.

- Batch costing is a form of job costing; many similar units comprising the batch may be used as a cost unit for ascertaining cost.

- In job costing, each job is treated as a separate cost unit, making it ideal for unique projects.

- The primary goal of job costing is to determine the overall price and profitability of a particular job.

- Consequently, a job costing system may contain a large number of specialized rules that are not broadly applicable to all jobs for which it is compiling information.

- (vi) Spoilage of material and defective work can be identified with specific job.

Differences between Cost Accounting and Financial Accounting

Many businesses struggle with accurately allocating overhead costs to individual projects. A daily or weekly analysis of materials requisitions, materials return notes and bills of materials is made and posted in the materials requisition journal. For cost Outsource Invoicing accounting purposes, a materials issue analysis sheet is prepared showing the cost of materials issued against the various job order numbers. Direct material cost is posted on the cost sheet relating to the particular production order while, indirect materials cost is treated as overhead costs.

Better budget and risk management

Otherwise, consider hiring an outside accountant to conduct a job costing audit and, perhaps, train you and your staff on how to do the calculations correctly on your own. But, to really get a handle on the ins and outs of job costing, consult with an accountant who has knowledge of your industry and who specializes in these niche calculations. You can implement job costing in your business on your own, but the process can get very complicated very quickly. Similarly, the engineering industry relies heavily on job costing because the scope and length of their work varies widely from project to project. Though this example shows how job costing can be used to create an estimate of future activity (the bid the keyboard manufacturer submitted), it can also be used to analyze past activity. Now that you’ve got the basic steps involved in job costing, let’s put the variables together in a real-world example to see how it all works.

Better cost control

- This helps in avoiding distortion of the year-to-year profit trend of the business.

- At any time during production, these partially manufactured products are collectively known as work in process (or goods in process).

- The limitation of time consuming can be removed by computerization and this can also reduce the complexity of the record keeping.

- The production control department sends a completion report to the costing department when a job is completed.

(4) A separate account is opened for each job to which all expenses incurred on that job, from the date of commencement till the date of completion are debited. (n) Under this method, the cost of each job and the profit or loss made on each job undertaken is found out separately. Any variance needs to investigate and make a change for the next job budget QuickBooks if necessary.

تم افتتاحه عام 1979 في منطقة القرهود، دبي، الإمارات العربية المتحدة

تم افتتاحه عام 1979 في منطقة القرهود، دبي، الإمارات العربية المتحدة

تم افتتاحه عام 1998، في البرشاء، دبي، الإمارات العربية المتحدة

تم افتتاحه عام 1998، في البرشاء، دبي، الإمارات العربية المتحدة

تم افتتاحه عام 2018 في الخوانيج، دبي، الإمارات العربية المتحدة

تم افتتاحه عام 2018 في الخوانيج، دبي، الإمارات العربية المتحدة